8" x 16"(203mm x 406mm)

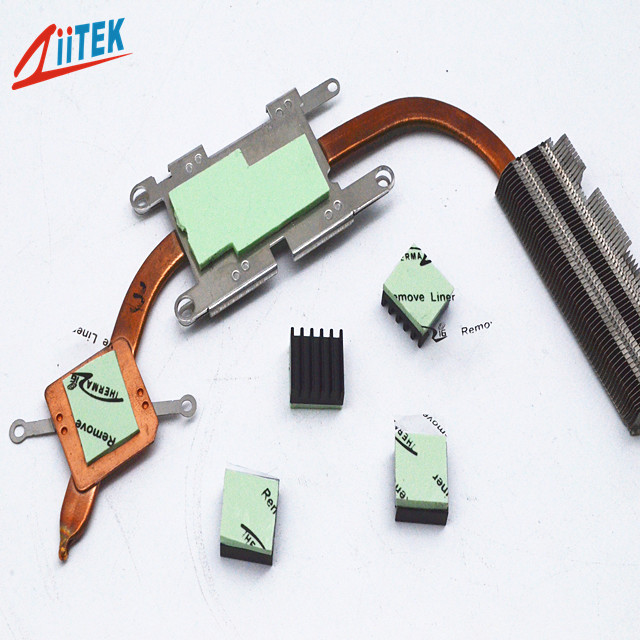

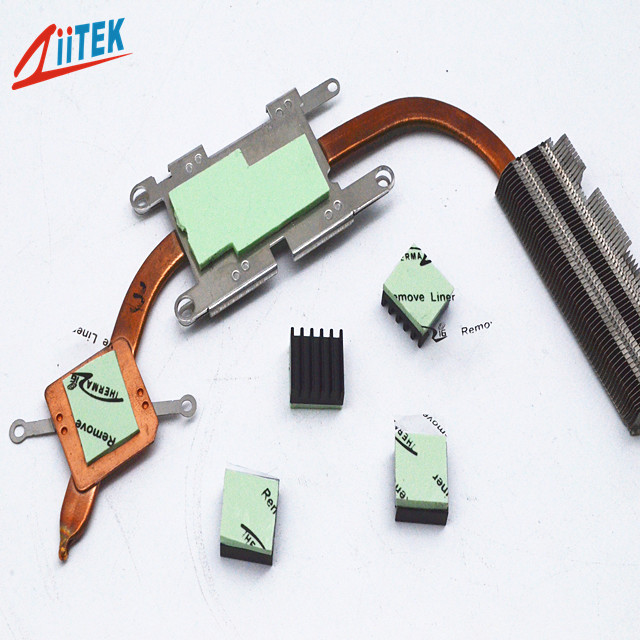

TIF™ series Individual die cut shapes can be supplied.

Packaging Details & Lead time

The packaging of thermal pad

1.with PET film or foam-for protection

2. use Paper Card To Separate Each Layer

3. export carton inside and outside

4. meet with customers' requirement-customized

Lead Time :Quantity(Pieces):5000

Est. Time(days): To be negotiated

Standard Thicknesses:

0.020" (0.51mm) 0.030" (0.76mm)

0.040" (1.02mm) 0.050" (1.27mm) 0.060" (1.52mm)

0.070" (1.78mm) 0.080" (2.03mm) 0.090" (2.29mm)

0.100" (2.54mm) 0.110" (2.79mm) 0.120" (3.05mm)

0.130" (3.30mm) 0.140" (3.56mm) 0.150" (3.81mm)

0.160" (4.06mm) 0.170" (4.32mm) 0.180" (4.57mm)

0.190" (4.83mm) 0.200" (5.08mm)

Consult the factory to alternate thickness.

Advantage

Ziitek has independent R&D team. This team is experience,

rigorous and pragmatic.

They undertake the core research and development tasks of Ziitek

thermal conductive materials. With well-equipped testing equipment,

we Ziitek can also do some tests with customers' samples, so we can

find a more suitable Ziitek materials for every customer.

Why Choose us ?

1.Our value message is'' Do it right the First time, total quality

control''.

2.Our core competencies is thermal conductive interface materials

3.Competitive advantage products.

4.Condidentiality agreement Bussiness Secrect Contract

5.Free sample offer

6.Quality assurance contract

TIF100-07E

Datasheet-REV02.pdf